Home >> Wave Springs >> Wave Spring Advantage

Wave Springs

Technical Resources

- Wave Spring Calculator

- Wave Spring Design Form

- Wave Spring Types

- Materials and Packaging

- Wave Spring Applications

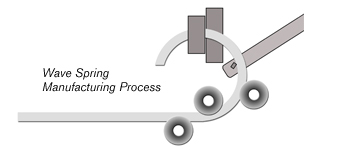

Wave Springs Manufacturing Process

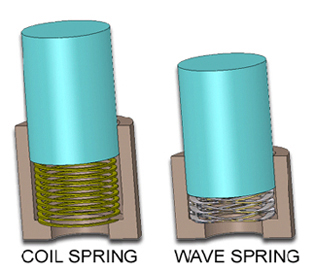

A wave spring is made from coiled flat wire with waves added to give it a spring effect. Wave springs are superior to coil springs in certain applications because they provide lower work heights with the same force. This not only provides for space savings, but also smaller assemblies that use less materials, hence lower production costs.

Our supplier coils pre-tempered flat wire made from rolled round wire as raw material. The on-edge-coiling process creates a circle with one or more turns to specifications in any diameter and any number of specific designed waves.

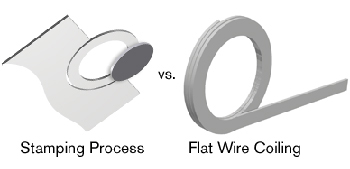

Flat Wire Wave Springs versus Conventional Stampings

- No material waste compared to stamped parts

- Rolled flat wire features edges with a radius -NO DAMAGE TO SHAFT/BORE

- No stamping burrs eliminates the grinding process

- No stamping through the metal grain -microstructures remain intact

- Microstructure offers better strength because the line of force in circumferential direction is not disturbed; risk of fatigue cracking and inconsistent loading in a lot is minimized

Advantage of Flat Wire Wave Springs

- Space saving in axial direction – 50% of the operating height could be reduced

- Bending load in the waves guarantees 100% axial transmission of load

- Only one spring must be handled comparing to stacked disc springs / wave washers.

- Space saving in radial direction compared to disc springs

- Single turn wave spring offers “cling in bore” option–spring is fixed and centered by itself

- “Cling on shaft” as assembly help option

- Low load tolerance at specified work heights

- More accurate spring rate and loads which could be better toleranced than 50% tighter than stamped wave washers or disc springs

- Unlimited range of forces could be created by using the factors wire size, wire form, no. of turns, turn configuration, no. of waves and wave form