Accueil >> Joints d’étanchéité >> Joints à l’huile >> Construction de joints d’étanchéité

La construction des joints d’arbre DMR™

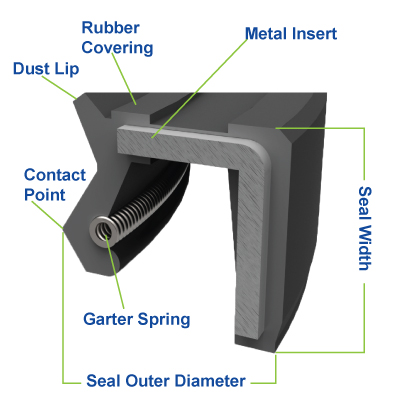

Les joints d’arbre rotatifs jouent un rôle clé dans la prolongation de la durée de vie des systèmes de roulements et la réduction des coûts globaux de maintenance de ces systèmes.

La fonction principale d’un joint d’arbre rotatif est de retenir les lubrifiants du système de roulement, permettant ainsi aux roulements de fonctionner à des niveaux de lubrification optimaux.

La fonction secondaire d’un joint d’arbre rotatif est d’exclure les contaminants du système, des contaminants qui peuvent à la fois endommager les roulements et réduire l’efficacité des lubrifiants.

Le catalogue en ligne de Daemar fournit une liste de styles et de tailles de joints d’arbre rotatifs standard.

Convient aux arbres allant de 1/4″ à 40″. Le guide de conception vous aide à sélectionner le style et le matériau de joint appropriés à votre environnement d’exploitation particulier.

Si la chaleur ou les attaques chimiques sont un problème, nous proposons des matériaux Viton® et polyuréthane ainsi que les silicones et nitriles standard. De plus, des paramètres de conception pour les configurations d’arbre et d’alésage sont fournis.

Ressources techniques

- Le joints d’étanchéité Catalogue en ligne

- Construction de joints d’étanchéité

- Matériau de l’élément d’étanchéité de propriétés

- Sélecteur de compatibilité avec les fluides

- La tolérance de joints d’étanchéité

- Conception de l’arbre

- Conception d’alésage

- L’installation du joints d’étanchéité

- Échange de joint d’arbre (national et SKF / CR)

- Glossaire de termes du joints d’étanchéité

- Feuille de conception de joints d’étanchéité

Boîtier

Matériaux de printemps

Boîtier

SAE

Application

Acier Carbone

1008-1010

General Purpose

Acier inoxydable

302/304

Corrosive Environments

Matériaux de printemps

SAE

Application

Acier à ressort au carbone

1070-1090

General Purpose

Acier inoxydable

302/304

Corrosive Environments

Boîtier

Matériaux de printemps

| Boîtier | SAE | Application |

|---|---|---|

| Acier Carbone | 1008-1010 | General Purpose |

| Acier inoxydable | 302/304 | Corrosive Environments |

| Matériaux de printemps | SAE | Application |

|---|---|---|

| Acier à ressort au carbone | 1070-1090 | General Purpose |

| Acier inoxydable | 302/304 | Corrosive Environments |