Home >> Slide >> Solid Metal Bushings >> TH650 Bearings

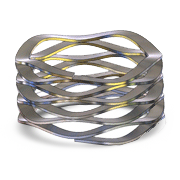

TH 650 Bearings

Machined cast bronze bearings offer technical and economic advantages. A combination of high loading capabilities, low weight and good corrosion resistance insures superior performance. DMR offers different grades depending on your applications and the tolerances of the TH 650 Bearings are much tighter than wrapped style bushings.

Features

1. May work without oil for long perlods of time

2. Extremely high load capacity, good anti-wear and lower friction

3. Particularly appropriate for low speed and high load applications

4. Suitable for reciprocating, oscillating or intermittent motion where it is difficult for oil film to be formed

5. Good chemical resistant and anti-corrosion characteristics

6. Can be used in wide range of temperature from -40°C to +300°C

Product Structure

The DMR TH 650 Bearings Series are cast bronze combined with special embedded solid lubricant plugs. The bronze allows the bushing to withstand high loads and the solid lubricant plugs allow for self-lubrication. The TH650 Series excels without pre lubrication under severe conditions of high or low temperatures with low speeds. The overall material combination provides a maintenance-free bushing solution, particularly for applications with high loads and intermittent or oscillating motion.

Typical Applications

The TH 650 Bearings Series can be utilized in applications that are dry, high temperature, high pressure, corrosive, water and other chemical environments where no oil lubrication can be applied.

| Solid Lubricants | ||

| Lubricant | Features | Application |

| SL1 Graphite + Add |

Excellent resistance against chemical attack and low friction. Temp. limit 400°C | General machines |

| SL4 PTFE+MOS2+CF |

Lower friction and good for water lubrication. Temp. limit 300°C | Water/sea lubrication, such as aboard ships, hydraulic turbines, gas tubines… |

| Technical Data | |

| Cu% | 65 |

| Zn% | 25 |

| Al% | 6 |

| Mn% | 4 |

| Density | 8.0 |

| Hardness HB | > 210 |

| Tensile Strength | >750 N/mm2 |

| Elongation % | >12 |

| Coefficient of Linear Expansion | 1.9*10-5/°C |

| Coefficient of Friction | 0.03 to 0.20 |

| Thermal Conductivity | 60 W(m*K)-1 |

| Temperature Limit (°C) | 300°C |

| Max. Load | 100 N/mm2 |

| Max. Speed | 15 m/min |

| Max. PV | 200 N/mm2*m/min |