Home >> Spirolox Retaining Rings >> Spiral Rings Material

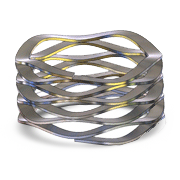

Spiral Rings Materials

Catalog-listed rings denote carbon spring steel with an oil finish. If a ring is required in one of the other available materials, a suffix code letter must be added to the part number. If a different finish is required, a suffix code letter must be added in the manner.

Technical Resources

Suffix Code Letters

Standard Materials

| Standard Materials | Code Letter |

|---|---|

| Spring Steel, Oil Finish | – |

| Stainless Steel Type 302 | S |

Special Materials

| Special Materials | Code Letter |

|---|---|

| Beryllium Copper | C |

| 17-7 PH | SC |

| 316 S.S. | 316S |

| Alloy A-286 | SN |

Available Finishes for Carbon Steel

| Finishes for Carbon | Code Letter |

|---|---|

| Cadmium plate bright | C |

| Cadmium plate, dichromate dip-iridescent | CD |

| Cadmium plate, iridire dip-clear | CI |

| Phosphate coat-zinc base | L |

| Parkerized | BP |

| Black Oxide | BX |

| Black Oxide | BX |

| Zinc Plate with dichromate dip | ZD |

| Passivation (for Stainless Steel Rings) | P |

Standard Material Types

Carbon Steel

Oil Tempered

SAE 1070-1090 high carbon tempered spring steel is a standard material for Spirolox retaining rings. Tensile strength and yield are maximized as a result of the oil tempered martensitic structure.

Stainless Steel

302 Stainless Steel is the standard stainless for Spirolox rings. This widely used material is specified because of its combination of corrosion resistance and physical properties. 302 obtains its spring temper condition by cold working. Through it is categorized as being a nonmagnetic stainless, 302 becomes slightly magnetic as a result of cold working. It is not hardenable by heat treatment. 302 has a silver-gray colour.

316 Stainless Steel is nearly identical in physical properties and heat resistance to 302, 316 provides additional corrosion resistance, particularly against pitting, due to its molybdenum chemical content. 316 is generally used in food, chemical and sea water applications.

Special Material Types

Super Alloys

Inconel X-750 is nickel-chromium alloy and is used most commonly in high temperature and corrosive environments. Two commonly specified tempers of Inconel are described below. Most commonly, Inconel X-750 is precipitation heat treated to a spring temper condition. In this stae, it has tempertaure resistance to 700°F.

A286 Alloy

In applications up to 1000 °F, this alloy exhibits similar properties to Inconel X-750. Its spring temper condition is obtained by precipitation hardening. A286 may be heat treated similar to spring temper and #1 temper Inconel

Elgiloy*

Known for its excellent resistance to corrosive environments and use at elevated temperatures, this relatively new spring material is now readily available from our factory. Commonly used in oil industry applications. Elgiloy is said to out perform over 600% better then 17-7 PH in load retention at 650 °F and provide over 100% more cycles than carbon steel, with out breakage.

Coppers

Beryllium Copper Alloy # 25 normally specified in a hard temper, this alloy produces excellent spring properties due to the combination of low modulus of elasticity and high ultimate tensile strength. The alloy gains its physical properties by precipitation hardening. In contrast to other copper alloys, beryllium copper has the highest strength and offers remarkable resistance to loss of physical properties at elevated temperatures.

Phosphor Bronze, Grade A offers fair spring properties, fair electrical conductivity and is rated a step below beryllium copper in performance.