Home >> Slide >> Dryslide Bushings >> THX Dryslide Bushings

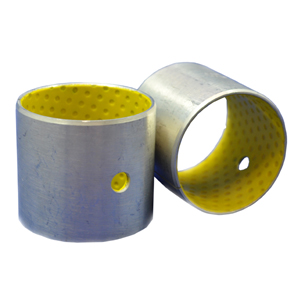

THX Dryslide Bearings

The THX Series has a composite structure consisting of a carbon steel backing onto which a porous layer of bronze is sintered and then impregnated with a co-acetal plastic. The polymeric surface has indentations in which the lubricating grease lies and protects the mating surface. Available in inch sizes.

Competitors equivalents: DXR, DX, P20

Product Description

The THX trademark denotes a range of sliding bearings produced from a material with a composite structure. The backing consists of carbon steel onto which a porous layer of bronze is sintered and then impregnated with a co-acetal plastic. The polymeric surface has indentations in which the lubricating grease lies and protects the mating surface. The main products in the THX range are the cylindrical bushings (DIN 1494), but thrust washers and strips are also available as well as special parts made to customer specifications.

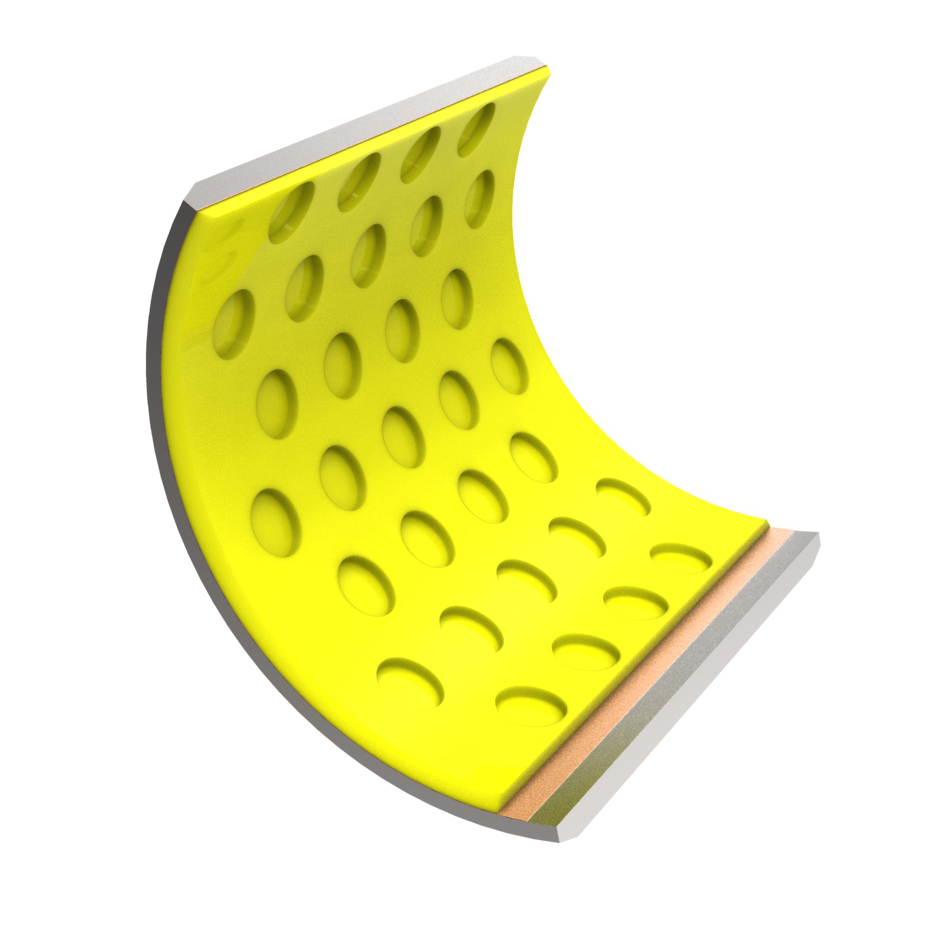

Product Structure

Steel bronze powder with Acetal Marginal bearings

1. POM (Acetal) 0.30-0.50mm: has high wear resistance and low friction. The bearing surface has a pattern of circular indents, which should be filled with grease on assembly.

2. Sintered bronze powder 0.20-0.35mm: provides maximum thermal conductivity away from the bearing surface, also serves as a reservoir for the resin mixture.

3. Low-Carbon Steel: provides exceptionally high load carrying capacity.

4. Zinc/Tin plating 0.002mm: provides good corrosion resistance.

The THX bushing can be used in rotary and oscillating applications.

Less maintenance requirements due to the long re-lubrication intervals. Less wear, less susceptibility to edge loading, and no absorption of water. The THX has good damping qualities and is resistant to shock loads.

Typical Applications

Recommended for applications involving intermittent operation or boundary lubrication.

Automotive: suspension joints, kingpin assemblies, automobile driving joint hinges, steering and other linkages, articulation joints, and rear chassis hinges.

Machine Tools: spindles in drill, grinding, and milling machines, and ram guide plates in multi ram presses.

Agricultural Equipment: gearboxes, clutch assemblies, bale trips and wheel caster swivels for bale accumulators, front axle pivot bearings, steering idler box bearings and kingpin bearings for harvesters…

The THX bushing is especially well suited for applications where lubricant cannot be supplied continuously or repeatedly.

Technical Data

| Max. Load | ||

|---|---|---|

| Static | 250 N/mm2 (36,000 psi) | |

| Load Capacity | 140 N/mm2 (20,000 psi) | |

| Max. PV | 3.0 N/mm2 *m/s | |

| (85,000 psi-fpm) | ||

| Temperature Range | Greased | 0.5 m/s (100fpm) |

| Oiled | 2.5 m/s (500 fpm) | |

| Coefficient of Fiction | 0.05-0.20 |