Home >> Shaft Seals >> Oil Seals >> Sealing Element Material Properties

Sealing Element Material Properties

Sealing Element (Rubber)

An oil seal normally consists of three basic components: Sealing Element, Metal Case, and Spring. The function of an oil seal is to prevent leakage along the shaft. This is mainly achieved by the sealing element. Materials normally used are Nitrile, Acrylic, Silicone, and Fluorinated Rubber.

Silicone Rubber (SI)

Silicone compounds operate effectively in a broad temperature range of -50 to 180° C. It is unsurpassed in its resistance to heat and low temperatures. The high lubricant absorbency of silicone minimizes friction and wear. It is usually used for crank shaft seals. Silicone has poor hydrolysis resistance. It should not be used in oxidized or hypoid oils.

Nitrile Rubber (NBR)

NBR is most commonly used material. It has good heat resistance properties, good resistance to oils, salt solutions, hydraulic oils, and gasoline. Operation temperatures are recommended from -40 to 120° C. It also functions well in dry environments, but only for intermittent periods. The disadvantage is poor chemical resistance.

Fluorinated Rubber (VI)

Fluorinated rubber is widely known under the DuPont trade name of Viton®. It has the best resistance to chemicals, and superior performance to high temperatures. The operation temperatures are recommended from -30 to 200° C. Though Viton® provides so many good prospects, it has the highest cost.

Polyacrylate Rubber (PA)

Acrylic rubber has better heat resistance than Nitrile. It is recommended for high surface speed environments. The operation temperatures are recommended from -20° C to 150° C. It should not be used with water or in temperatures below -20° C.

Lubrication

Oil seals are designed to operate with either oil or grease lubrication. Insufficient levels of lubrication cause excessive heat build up and reduce the life expectance of the seal lip and the shaft.

When selecting a lubricant ensure that the lip material is compatible with the lubricant base materials. Before installation both the seal and shaft should be sufficiently lubricated.

MATERIAL PERFORMANCE

NITRILE

PA

SILICONE

VITON

Temperature Range (°C)

-40 to 120

-20 to 150

-50 to 180

-30 to 200

Hardness (Shore)

70/80

70/80

75/85

70/80

Wear Resistance

O

X

XX

X

Costs

Most economical

3rd costly

2nd costly

Highest

MATERIAL CHEMICAL RESISTANCE

| NITRILE | PA | SILICONE | VITON | |

|---|---|---|---|---|

| Inorganic acids | ||||

| Organic acids | XXX | XX | XX | |

| Alkali | XX | O | O | O |

| Salt | O | O | O | O |

| Alcohol | XXX | O | O | O |

| Esters | XXX | XXX | XXX | |

| Phenol | XXX | XXX | O | |

| Ketones | XXX | XXX | XX |

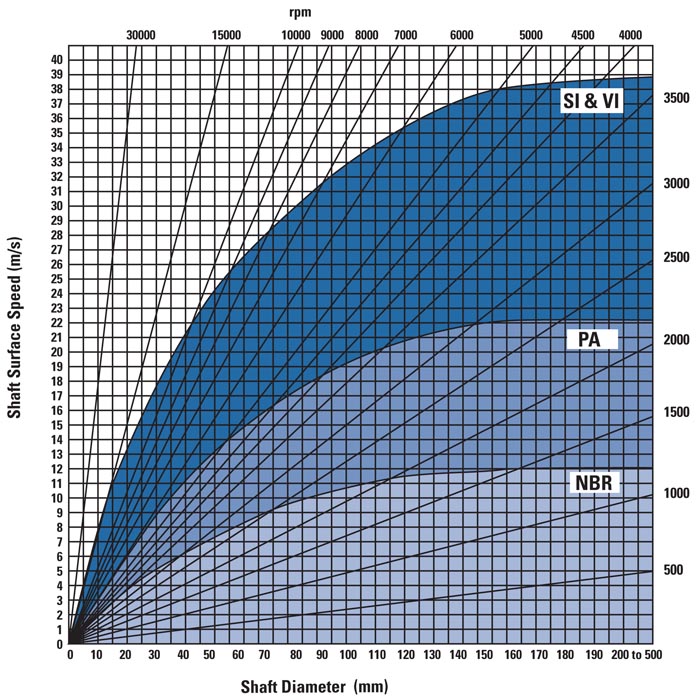

RPM and Surface Speed

The following table shows the permissible surface speed and RPM’s for various sealing element materials and shaft diameters.