Home >> Shaft Seals >> Oil Seals >> Construction of DMR Seals

The Construction of DMR™ Shaft Seals

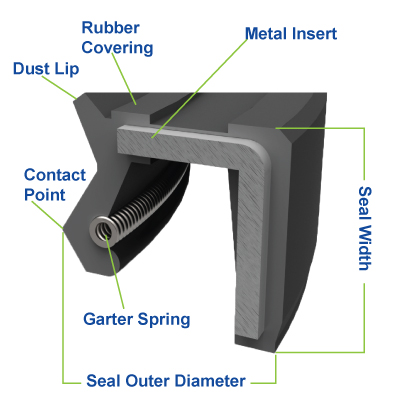

Rotary shaft seals play a key role in extending the operating life of bearing systems and reducing the overall costs of maintaining these systems.

The primary function of a rotary shaft seal is to retain bearing system lubricants therefore allowing the bearings to operate in optimal levels of lubrication.

The secondary function of a rotary shaft seal is to exclude contaminants from the system, contaminants that can both damage bearings and break down the effectiveness of lubricants.

Daemar’s Online catalogue provides a listing of standard rotary shaft seal styles and sizes.

Accommodating shafts ranging from 1/4” to 40”. The design guide offers assistance in selecting the appropriate style and material of seal for your particular operating environment.

If heat or chemical attack are a concern we offer Viton®, and polyurethane materials as well as the standard silicones and nitriles. Additionally, design parameters for shaft and bore configurations are provided.

Case Material

Spring Materials

Case Material

SAE

Application

Carbon Steel

1008-1010

General Purpose

Stainless Steel

302/304

Corrosive Environments

Spring Material

SAE

Application

Carbon Spring Steel

1070-1090

General Purpose

Stainless Steel

302/304

Corrosive Environments

Case Material

Spring Materials

| Case Material | SAE | Application |

|---|---|---|

| Carbon Steel | 1008-1010 | General Purpose |

| Stainless Steel | 302/304 | Corrosive Environments |

| Spring Material | SAE | Application |

|---|---|---|

| Carbon Spring Steel | 1070-1090 | General Purpose |

| Stainless Steel | 302/304 | Corrosive Environments |